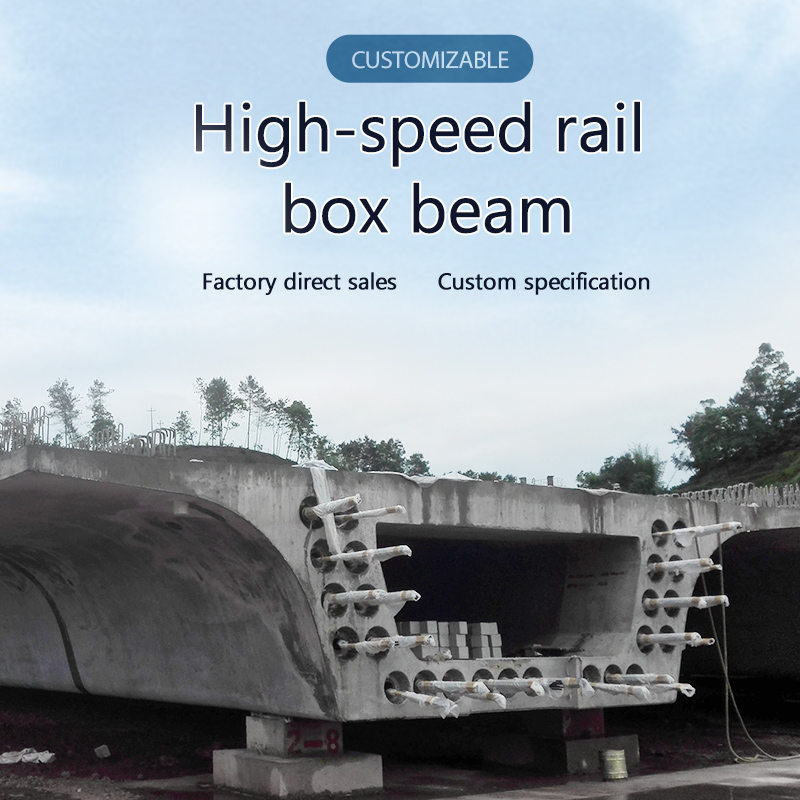

Customized High-speed Rail Box Beam Made In China

2022-10-19

railway box girder formwork is divided into two major parts: inner and outer formwork, of which the outer formwork is divided into 3 parts: bottom formwork, side formwork, and end formwork. The inner mold is composed of 3 parts: walking mechanism, hydraulic and support system and formwork system. The inner die is divided into two kinds.

I. Hydraulic internal mold

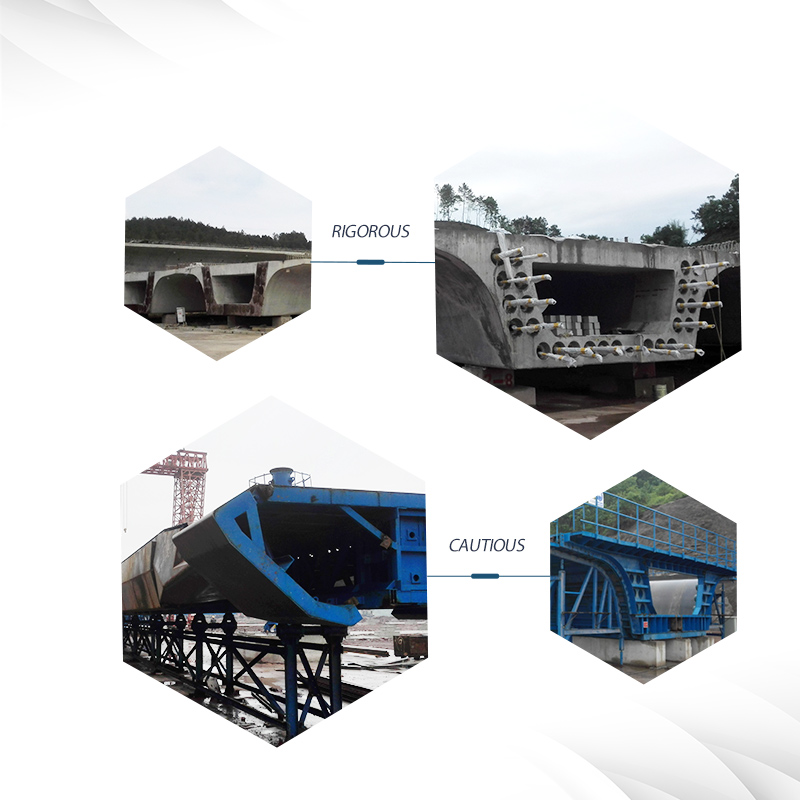

Advantages: good integrity of steel mold; large overall stiffness; smooth and clean surface; smooth and beautiful concrete surface; easy to ensure the appearance of the beam size; support and demolition of the mold can be completed at one time, reduce labor and reduce the labor intensity of workers.

II. Assembly type inner mold

Considering the labor intensity and structural form of construction in the box, the formwork in the corner is reduced, and the principle of flat and side formwork is that the weight of a single block does not exceed 35Kg, and the size of the block is uniform and interchangeable. This brings fast and convenient manufacturing and processing, less material for steel structure, low cost, and easy to change beam shape. The manufacturing cost of assembled internal mold is low, only equivalent to 1/5~1/10 of hydraulic type overall internal mold, and the process time of occupied pedestal is short and easy to maintain.

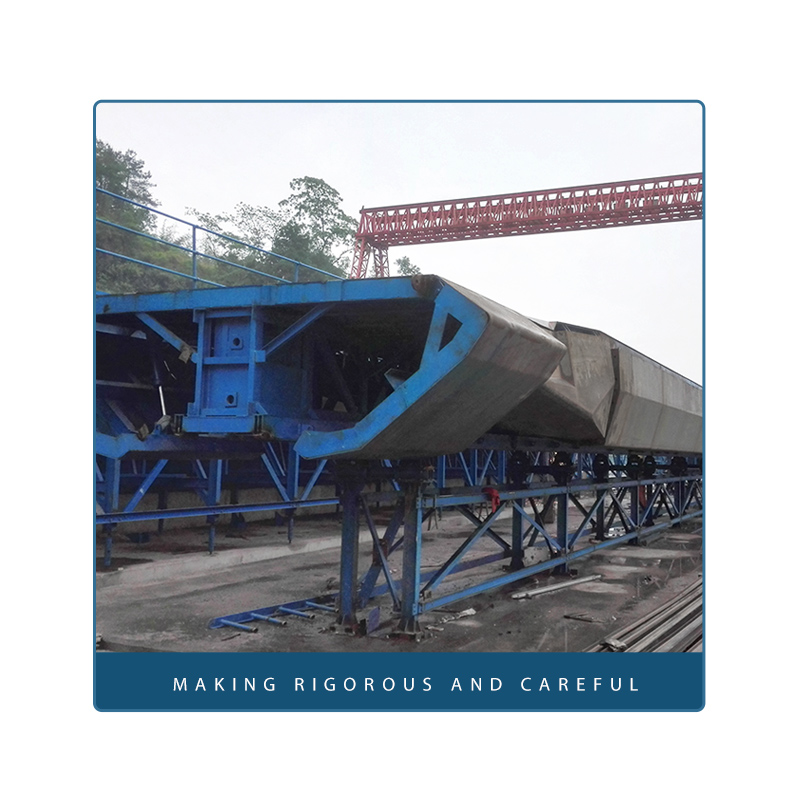

Process characteristics: 1. Uniform planning of site layout and hardening, scientific and reasonable zoning. The main control point is the girder making pedestal, and each functional area is reasonably set up along the surrounding area, and the hardening site is hardened according to the different weight of the running vehicles and machines, which saves investment. 2. The design of the formwork structure is novel, using the whole outer and inner moulds, the side and bottom moulds are fixed in the box girder prefabrication, and the inner moulds adopt the full hydraulic automatic control of the track walking mode, which saves the demolition and installation time and speeds up the girder making speed. 3. The reinforcing steel is tied by using the tire and clamp to control the material, and the overall tying tire is tied, and designed to use the overall lifting tool to lift the reinforcing steel cage. The pre-stressing is carried out in three stages: pre-tensioning, initial tensioning and final tensioning, which can effectively control the early cracking and creeping arching of the beam. 5. Vacuum-assisted grouting process is adopted for pipeline grouting, which can effectively ensure the fullness of the pipeline slurry.

Chengdu Sanyi Road and Bridge Equipment Co., Ltd. was established in 2011. It is a company specializing in the production and processing of road and bridge equipment - steel formwork and other products. It has a complete and scientific quality management system. It is the "Top 100 Bidding and Procurement Suppliers in Sichuan Construction and Building Materials Industry in 2021". The company is an enterprise integrating investment and financing, construction management, and operation of infrastructure projects as its main business, and integrates the development of multiple industries. Mainly engaged in domestic and international road, bridge, tunnel, municipal, transportation facilities and other project investment, construction and project construction management services. Chengdu Sanyi Road and Bridge Equipment Co., Ltd. has rich construction experience and strong technical force, and has established a good reputation in the industry and society. Unity, innovation, pragmatism and progress are the unswerving pursuit of the company. The company cherishes every honor, adheres to the business tenet of "quality first, customer first, prospering with quality, and winning with excellence", and constantly contributes excellent products to the society, complements the advantages of all sectors of the society, and creates brilliant together!

905331432@qq.com

Huang Xiaohui